Fitting Double Length Wall Boards Over 6m In Length

Standard timber for construction is supplied to the mill resulting in a maximum length of 6.0m once it has been milled and prepared for use as a wall board.

Although a 6.0m wall can provide a substantial building, it sometimes is left wanting - so what happens when the project demands a wall length in excess of 6.0m ? Simple (!) we need to produce a join that is both practical to produce, aestetically pleasing and also strong.

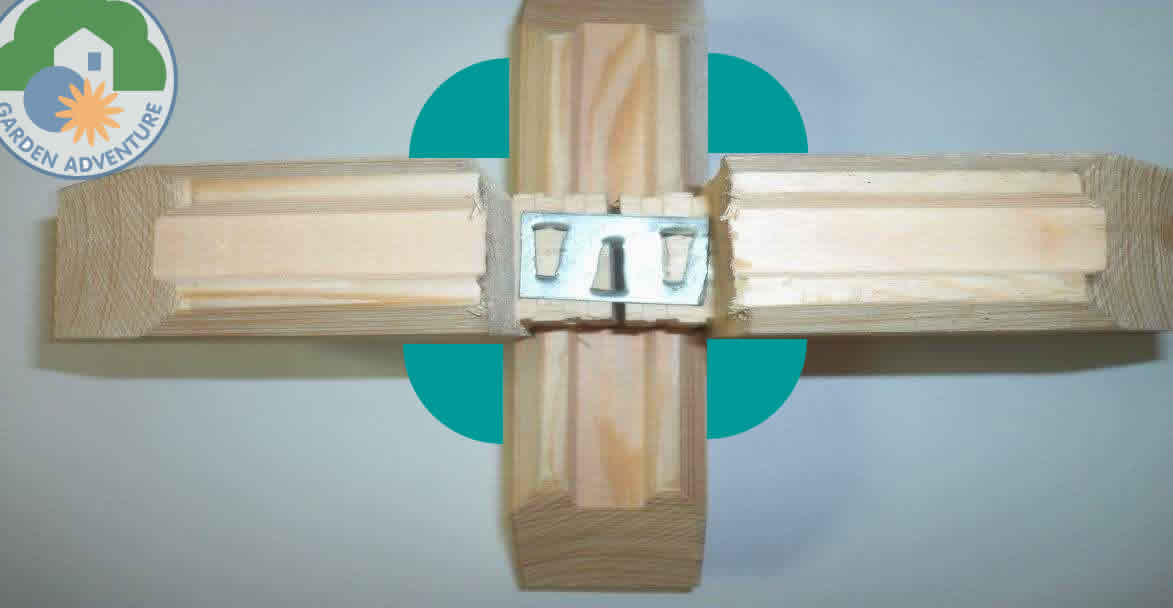

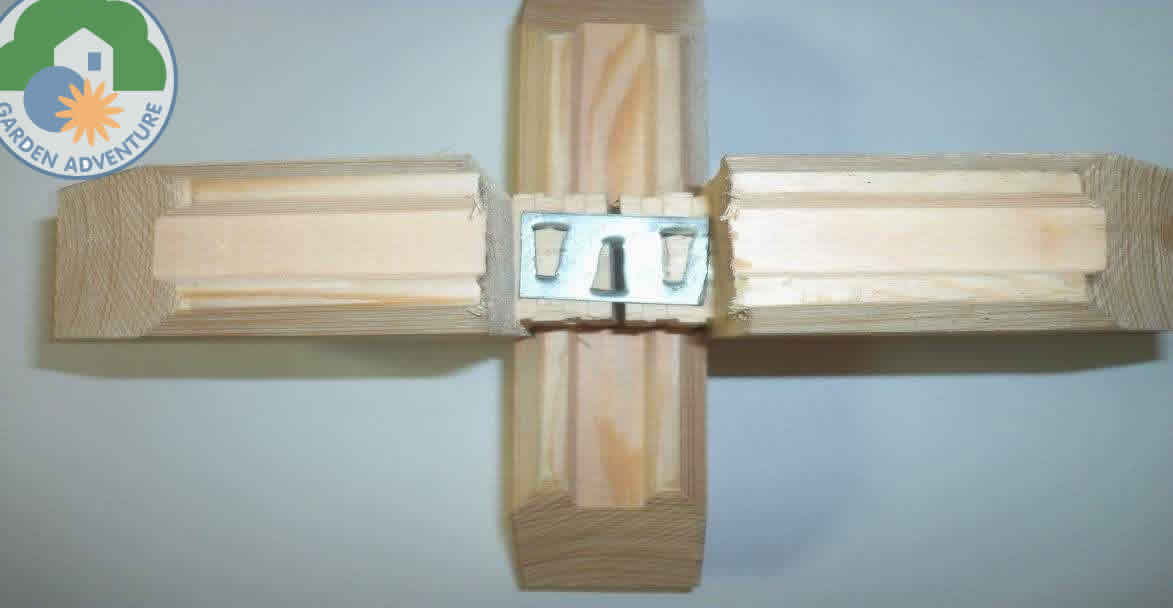

Here is a typical join showing the two ends viewed from the underside :

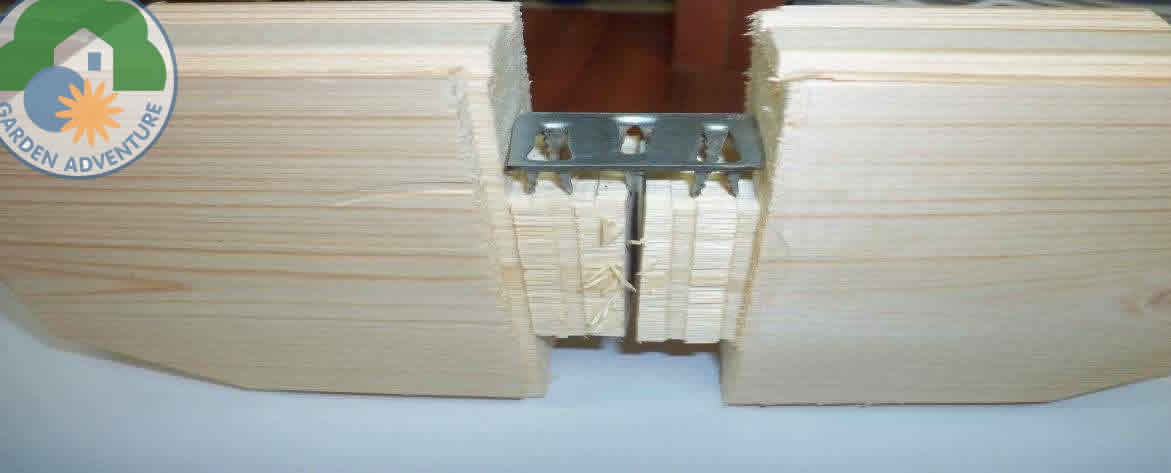

When constructing, these logs need to be pushed together as tightly as possible :

In order to hold them in place, the kit supplies metal plates with spikes in - these should be applied once you are satisfied the join is tight along its length :

The trick is to ensure the logs are as tight as possible along their length - as soon as one join becomes a little loose, it is impossible to get the remaining logs to sit correctly.

How do you put pressure on mis-behaving logs to encourage a proper fit ?

We use a Ratchet Load Strap :

Attach one end to an outside wall, the other end to the opposite outside wall along the length of the log where the join occurs. Ratchet the logs together, this will pull the two ends of the logs together to allow a tight fit and t secure with the metal plates. Once you are satisfied the logs are held in place release the ratchet carefully and continue the build.

A correctly made join should look like this :

You may need to run a bead of silicone down each internal corner of the join to tidy it up :